| |

|

|

|

| |

|

Welcome to the News &

Press releases page. Here you will

find pictures, videos and links to the

students' research endeavors this year!

Please check back often for updates.

Please also view the past news releases by

following the links to the right. |

|

|

|

|

|

|

|

|

05-26-15 |

|

Student Research

Team:

BCS Technologies characterizes their YBCO

superconductive nanofibers!

On Wednesday,

June 10th, Nicholas Pleim and E.J. Bevenour

tested the conductivity of their YBCO

superconducting nanofibers!

Below is a

synopsis of their research findings:

| |

Superconductive

state properties were observed in

our samples, from both

electrospinning and spin-coating

processes, of a Yttrium Barium

Copper Oxide precursor solution with

a Poly(Acrylic) Acid carrier polymer

after being pyrolysed in a tube

furnace. The samples, on a

one-by-one inch alumina ceramic

square, were submerged in liquid

nitrogen, and put under a

four-point-probe conductivity meter.

Current was sourced between one and

ten nano-amps, and Voltage, sheet

Resistance, and Temperature were

measured as the sample heated in

air. The samples heated too quickly

to measure a zero-ohm resistance,

but an increase in electrical

resistance was measured as the

temperature of the sample increased.

Also, when cooled in the presence of

a magnetic field, the samples

retained magnetic properties even

after heating. Despite the limits of

the equipment, symptoms and signs of

a superconductive state, including

SEM-imaging as well as

electrical-thermal and magnetic

properties, were observed. Although

our findings are inconclusive, it is

inferred that the samples of YBCO

nanofibers and films were

successfully superconductive.

|

A very

special thank you to Drexel University, Dr.

Michel Barsoum and his undergraduate

student, Cooper Voigt, for running the YBCO

nanofiber specimens in the tube furnace for

us!

Liquid nitrogen for the tests.

Measuring the temperature.

Measuring the temperature.

Running 4 Point Probe analysis with a Signatone 302 and a Keithley 2450

source meter.

|

|

Twitter post!

|

|

05-26-15 |

|

Student Research

Team:

BCS Technologies characterizes their YBCO

superconductive nanofibers!

On Wednesday,

June 10th, Nicholas Pleim and E.J. Bevenour

tested the conductivity of their YBCO

superconducting nanofibers!

Below is a

synopsis of their research findings:

| |

Superconductive

state properties were observed in

our samples, from both

electrospinning and spin-coating

processes, of a Yttrium Barium

Copper Oxide precursor solution with

a Poly(Acrylic) Acid carrier polymer

after being pyrolysed in a tube

furnace. The samples, on a

one-by-one inch alumina ceramic

square, were submerged in liquid

nitrogen, and put under a

four-point-probe conductivity meter.

Current was sourced between one and

ten nano-amps, and Voltage, sheet

Resistance, and Temperature were

measured as the sample heated in

air. The samples heated too quickly

to measure a zero-ohm resistance,

but an increase in electrical

resistance was measured as the

temperature of the sample increased.

Also, when cooled in the presence of

a magnetic field, the samples

retained magnetic properties even

after heating. Despite the limits of

the equipment, symptoms and signs of

a superconductive state, including

SEM-imaging as well as

electrical-thermal and magnetic

properties, were observed. Although

our findings are inconclusive, it is

inferred that the samples of YBCO

nanofibers and films were

successfully superconductive.

|

A very

special thank you to Drexel University, Dr.

Michel Barsoum and his undergraduate

student, Cooper Voigt, for running the YBCO

nanofiber specimens in the tube furnace for

us!

Liquid nitrogen for the tests.

Measuring the temperature.

Measuring the temperature.

Running 4 Point Probe analysis with a Signatone 302 and a Keithley 2450

source meter.

|

|

Twitter post!

|

| |

|

|

|

05-26-15 |

|

Drexel University,

Dr. Barsoum assist research team BCS

Technologies!

BCS Technologies

has been researching and designing high

temperature superconductors this school

year. One of the major processes in

developing the highly conductive nanofibers

is the use of a tube furnace to process

their materials. Nicholas Pleim,

senior student, visited with Dr. Michel

Barsoum at Drexel University today to drop

off his team's electrospun and spin coated

samples for processing in their tube

furnace. The tube furnace will prepare

their fibers at temperatures exceeding 900

0C for over 16 hours! Thank

you so much Dr. Barsoum and his

undergraduate student, Cooper Voigt!

Please check back soon for further

information! |

|

Nicholas Pleim, BCS Technologies, in front of the tube furnace at Drexel

University to process their electrospun superconductor nanofibers!!

|

| |

|

|

|

04-17-15 |

|

Students begin

testing custom

machined nanofiber

alignment apparatus!

EJ Bevenour and Nicholas Pleim are currently

testing an apparatus they designed in

Autodesk Inventor to collect aligned

nanofibers for high temperature

superconductive polymers which they plan to

electrospin next week.

The disc is designed to spin at 1200rpm

while holding eight scanning electron

microscope mounts (SEM stubs) and four

single sapphire substrates.

The students plan to electrospin YBCO

(yttrium barrium copper oxide) nanofibers to

the disc and test their conductivity

utilizing liquid nitrogen, a Keithley 2450

Source Meter, Interdigitated Microsensor

Electrodes and a Signatone Four Point Probe.

The disc

and the materials were donated and machined

by Edward Stachowicz at EDS in Philadelphia.

Thank you so much Mr. Stachowicz!!! |

|

Custom-designed electrospinning apparatus!

|

| |

|

|

|

03-31-15 |

|

Students wetspin,

spincoat and electrospin polyacrylonitrile

and copper composite nanofibers!

Students in

research team Electrifiber processed a

polyacrylonitrile copper composite solution

utilizing three different methodologies:

Wetspinning, spincoating and

electrospinning!

Fibers

were analyzed with the our new Zeiss

microscope. Next will be electrical

characterization with our new Keithley 2450

SMU we just received! Check back soon for

more information! |

|

Wetspinning, spincoating and electrospinning!

|

| |

|

|

|

03-19-15 |

|

Dow Engineers Visit

North Penn High School Engineering Academy?

On

Thursday, March 19th, five engineers from

The Dow Chemical Company visited the Future

is NEAR program to learn about the research

endeavors the students are performing this

year.

The

students presented their research, including

the successes and challenges they have had

so far this year. The engineers offered

invaluable insight, ideas and suggestions to

help them prepare the design of their next

set of experiments. Thank you so much! Check

back soon for more information soon! |

|

DOW Engineers Visit NPHS!

|

| |

|

|

|

03-16-15 |

|

What are

Interdigitated Microsensor Electrodes?

Interdigitated

Microsensor Electrodes (IMEs) are a family of

devices developed by ABTech Scientific, Inc.

in Richmond, Virginia.

They are designed to aid in the optical and

electrical characteristics of thin films,

coatings and polymer nanofibers. Students in

the engineering academy will be utilizing

these devices to help them characterize the

conductive and superconductive nanofibers

they are producing in class. More to come

soon! |

|

IMEs!

|

| |

|

|

|

03-16-15 |

|

Students Melt-Electrospun

PCL!:

Students in the Deltatech research team,

Jacob Boyce, Jack Pedicone and Chris Sibel

were able to successfully melt-electrospin

PCL (polycaprolactone) for the first time at

North Penn High School today.

The fibers were analyzed utilizing our new

Zeiss Primo Star microscope!

Check back soon for images of the studentsí

research endeavors! |

|

Deltech Solutions: Melt-Spinning!

|

| |

|

|

|

03-11-15 |

|

We now have "macro"scale

vision!:

Zeiss Primo Star with ERc 5s Camera

A Zeiss Primo Star microscope was delivered

and installed today by Thomas Pogash of

Hitech Instruments, Inc.

Thanks to a generous donation from Dow, the

students of the North Penn High School

Engineering Academy now have the ability to

characterize much of their research with a

high quality, research grade microscope from

Zeiss!

Check back soon for images of the studentsí

research endeavors!! |

|

We have vision!

|

| |

|

|

|

03-03-15 |

|

Custom Designed /

3D Printed Spin Coater Chuck:

Brandon Berlin, Rahul Pendurthi and Alex

Pham are developing a custom spin coater

from a low-cost mini-centrifuge.

The team designed an adapter chuck in

Autodesk Inventor to mount their Flourine

Tin Oxide doped glass slides to their

centrifuge and then utilized one of the 3D

printers available in the engineering

academy to create their custom chuck. The

device is capable of spin speeds of 12,000

rpm; however, their initial spin coats will

be run at only 3,000 RPM.

The team hopes to utilze their device to

create a novel photocatalytic layer for more

efficient solar cells.

|

|

We have vision!

|

| |

|

|

|

02-15-15 |

|

We Have "Vision"! Angstrom Scientific Loans

Scanning Electron Microscope to

North Penn High School Engineering Academy

Students:

On Friday, the Engineering

Academy seniors at North Penn High School

received, on loan, a scanning electron

microscope (SEM) from Angstrom Scientific to

aid in the characterization of their

research.

Read More.... |

|

We have vision!

|

| |

|

|

|

02-07-15 |

|

Engineering Academy students Present at

Philly Materials Day:

North Penn High School Engineering Academy

students present at Philly Materials Day!

Students in two research teams of the

Engineering Design and Development (EDD)

course of the Engineering Academy presented

their research on Saturday, February 7, 2015

from 10am to 4pm.

Read More... |

|

Students to present at Philly Materials Day Saturday 2/7/15!

|

| |

|

|

|

02-02-15 |

|

Engineering Academy students to Present at

Philly Materials Day:

NPHS Engineering

Academy students will be presenting at

Philly Materials Day on Saturday, February

7, 2015 from 10am - 4pm. Please visit

their website for more information at:

www.phillymaterials.org! |

|

Students to present at Philly Materials Day Saturday 2/7/15!

|

| |

|

|

|

01-15-15 |

|

Engineering Academy students visit the

Laurell Technologies Corporation:

NPHS engineering

academy students visit the

Laurell

Technologies Corporation in North Wales to

learn about the spin coating process and to

tour their manufacturing and engineering

facilities. L to R: Alex Noce, Joe DiFeo,

Rahul Pendurthi, Mr. Boyer, Nick Pleim and

Chris Sibel |

|

Students visit Laurell Technologies Corporation in North Wales!

|

| |

|

|

|

01-14-15 |

|

BCC Biotech begins antibacterial fabric

research:

NPHS engineering academy students in

research team BCC Biotech are working on the

development of chitosan nanofibers. Their

research this year is focusing upon the

development of antibacterial fabrics that

also have bioabsorbable features. |

|

BCC Biotech developing a chitosan solution to create antibacterial

nanofibers!

|

| |

|

|

|

11-24-14 |

|

2014 Engineering

Academy Graduates Visit from PSU Materials

Science & Engineering:

Thank

you so much to Victoria Christensen and Nick Bonsignore, 2014 Engineering Academy

graduates, for coming out to share

materials demonstrations and their experiences in the

Materials Science and Engineering program at

Penn State Universityty! |

|

2014 Engineering Academy graduates visit from PSU Materials Science &

Engineering program @ PSU!

|

| |

|

|

|

11-21-14 |

|

Engineering academy students in team

Electrifiber took their

first attempt at a new way to create polymer

fibers: wet spinning. In

wet-spinning, the

spinneret remains submerged in a chemical

bath that leads the fiber to precipitate,

and then solidify, as it emerges out of the

spinneret holes. Acrylic, rayon and spandex

fibers, all are manufactured through wet

spinning. Students plan to design a wet

spinning apparatus with the hopes of

producing conductive fibers.

|

|

Electrifiber: Results from first wet spinning experiment.

|

| |

|

|

|

11-19-14 |

|

Meltspinning Research - A New Process for

Students to Create Polymer Fibers

Student

research team, DeltaTech, is working on the

development of a custom-designed melt

spinning apparatus and are currently testing

the properties of a thermal tape to control

the temperature of their polymers.

Melt Spinningng is

used for the polymeric fibers or the

polymers that can be melted. The polymer is

melted and then pumped through a spinneret.

The cooled and solidified molten fibers get

collected on a take-up wheel. The fibers,

when stretched in both, the molten and solid

states, facilitate orientation of the

polymer chains along the fiber axis.

|

|

DeltaTech: Thermal tape test. |

| |

|

|

|

|

11-14-14 |

|

Students Began Electrospinning Polymer

Nanofibers

Student research teams began electrospinning

their first polymer nanofibers from their

own developed polymer solutions.

Check back soon for more work to be

completed by the students this year and new

types of polymer fiber development

techniques! |

|

Student research: Electrospinning this first polymer nanofibers. |

| |

|

|

|

10-16-14 |

|

Engineering Academy Creates Hydrophobic

Phosphorescent Nanofibers

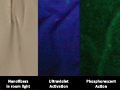

Research student, Chris Sibel, designed an

experiment to see if Europium based

phosphorescent powders embedded in a

hydrophobic polymer nanofiber would glow in the dark

after being exposed to uV light. The

experiment worked! |

|

Phosphorescent nanofibers! |

| |

|

|

|

|

10-03-14 |

|

Ametek / Pittman Manufacturing Day Facility

Tour

Thank you so much to Ametek Precision Motion

Control and Pittman Motors for hosting the

North Penn High School Engineering Academy

for Manufacturing Day! |

|

Ametek Precision Motion Control and Pittman Motors |

| |

|

|

| |

|

|

|

| |

|

|